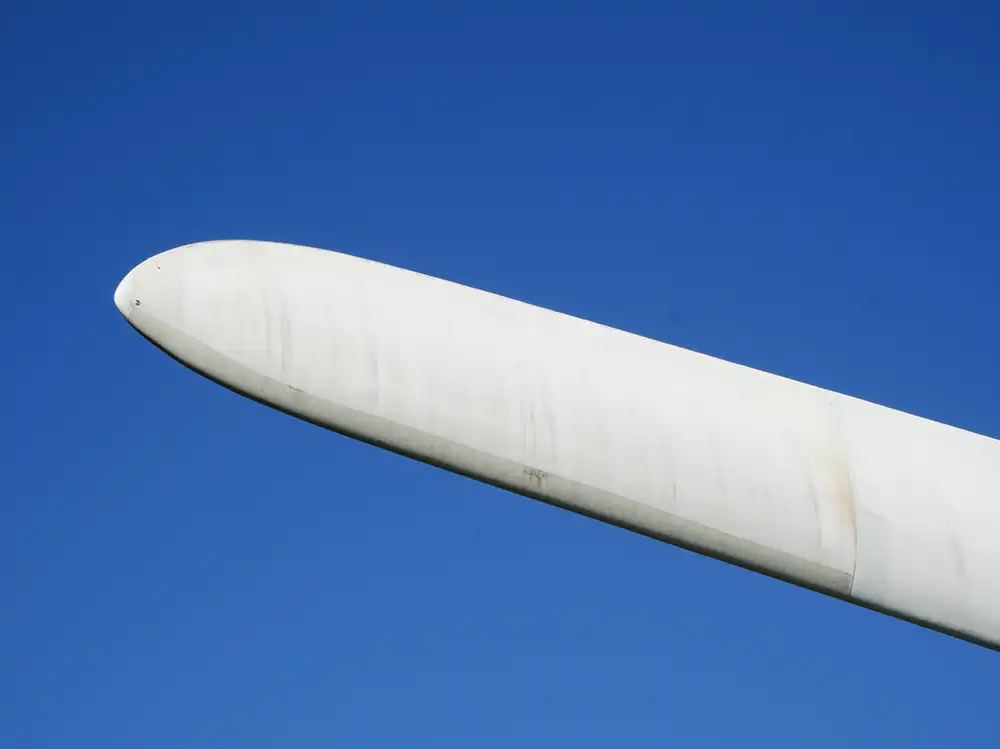

Drone Blade nspections: The Key to Predictive Maintenance and Downtime Prevention

As a wind turbine owner or operator, you know the stakes: every hour a turbine sits idle due to blade damage is lost revenue. The harsh truth is that even minor blade defects—cracks, erosion, or lightning damage—can escalate into costly structural failures if not detected early. Traditional inspection methods are slow, expensive, and reactive. If you're relying on rope-access crews or waiting for visible signs of failure, you're already behind. Drone blade inspections are no longer a novelty—they are a strategic asset for turbine owners serious about uptime, safety, and long-term performance. With drone technology, you can shift from reactive to predictive maintenance and protect your revenue by identifying and addressing issues before they lead to critical failures.

Unplanned Downtime

Unplanned downtime is one of the most significant operational headaches. A single turbine offline for a few days can cost tens of thousands in lost energy production. Drone inspections can be scheduled routinely—often between weather windows—to quickly assess blades without halting operations for extended periods. With real-time or same-day data delivery, decisions can be made faster, keeping turbines spinning and revenue flowing.

Hidden Damage and Missed Defects

Traditional visual inspections often miss early-stage damage, especially internal or hard-to-reach areas. Drone-mounted high-resolution and thermal imaging cameras can detect subtle defects invisible to the naked eye. AI-assisted analysis identifies microcracks, delamination, and lightning strike signatures long before they become serious, allowing for proactive repairs instead of emergency interventions.

High Inspection Costs

Using rope-access teams or cranes can cost thousands per turbine and takes hours or even days. With drones, a complete blade inspection can be done in under an hour—without shutting down the turbine for long periods. Reduced manpower, no heavy equipment rentals, and faster turnaround all mean significantly lower costs per inspection cycle.

Lack of Historical Damage Tracking

Without accurate, ongoing records, it’s difficult to monitor how defects progress or which turbines are most at risk. Drone inspections provide consistent, geotagged, time-stamped data stored in cloud-based platforms. You get a complete damage history for each turbine, helping you forecast maintenance budgets, plan replacements, and comply with OEM warranty terms.

Enable Predictive Maintenance Across Your Fleet

Predictive maintenance isn’t just a buzzword—it’s the difference between staying ahead of failures and reacting to disasters. Drone inspections are a cornerstone of effective predictive strategies. Whether you manage 10 turbines or 1,000, the scalable nature of drone programs means your entire fleet can be inspected efficiently and consistently. With periodic drone inspections, turbine owners can:

- Establish damage progression trends

- Schedule blade repairs during low-wind periods

- Optimize maintenance crew deployment

- Avoid peak energy loss during high-demand seasons

Conclusion

Wind turbine owners cannot afford the cost of guesswork or outdated inspection methods. Drone blade inspections offer the precision, speed, and data-driven insight required to make smarter maintenance decisions. Protect your investment, minimize downtime, and gain control over your maintenance strategy. If you're serious about maximizing turbine lifespan and profitability, drone inspections are no longer optional—they're essential.

Get in touch

Contact us via telephone, email or using the following form.

- Address

- SENSOAR LIMITED

5 South Charlotte Street

Edinburgh

EH2 4AN - Telephone

- +44 (0)131 510 8959

- contact@sensoar.io